Mr_Michael_or_Mike wrote:Hi all,

I wonder what is the optimal spring floor for Judo? Let's say you have a concrete floor and, want to go further than just laying the tatami, or flexi-roll on that. I've read about and, practiced upon sub-floors made of tires and, foam blocks. I've seen gymnastics floors with real steel coil springs underneath. What is the optimal floor for long term Judo practice? What do they use in Japan, at the Kodokan? Do they use steel coil springs, or some type of wooden spring floor, like many old dance halls once had. What is the best floor to go under the tatami?

Thanks.

This is a good question. It has been asked before and the information is too little commonly known. I have made a folder on my computer to compose a scholarly papers on this matter as from responses previously given I can only derive that the facts are not generally know. With facts I mean the hard data and parameters that actually measure and explain the differences and that can be compared. Too often the responses boil down to "this is how we've done it and it's awesome and the best floor in the world" (... says the jûdôka who is a yellow belt and has visited two local dôjô in his entire life).

To the best of my knowledge there exist only one Western jûdô federation which had taken things seriously and actually published standards for different approaches, and that is the FFJDA. They actually have a pdf-booklet that explains those standards.

There do exist dôjô in the West which have a decent floor but many of these are pretty old since with today's standards it would be an expensive job to make such a floor. The biggest problem though as with so much in jûdô is that people simply lack the knowledge, so they start guessing or experimenting, or copying in some way what they think is or needs to be done. This is also the reason that I said that there is a need for these procedures to be put together so that the knowledge is available in Western languages. Some time ago, at the beginning of this new forum I wrote a post in which I tried to briefly explain some of these principles, but it was as is often the case, met with anger particularly by those who had built a tatami floor that lacked these standards.

I realize it's a tough job, but that doesn't mean people can't at least be explained what these standards are and how to achieve them.

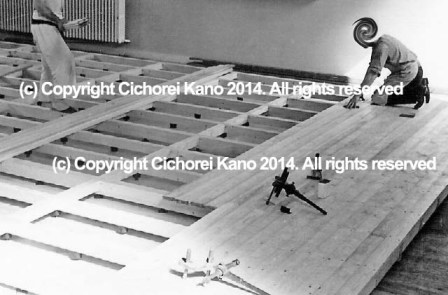

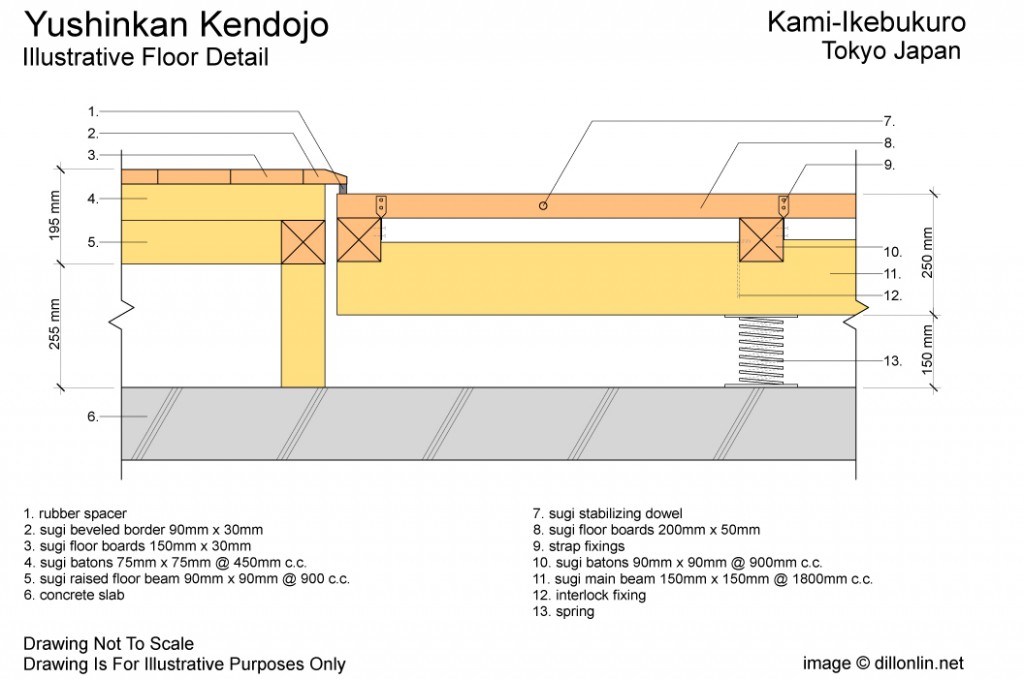

In essence, what happens is that the concept of the tatami floor is part of the building plans. It is not normally "added afterwards". The concrete floor needs to be poured lower than what your final floor would be, so it is actually a sunk floor. When the concrete is floored at calculated intervals cardboard cilinders are constructed that are filled with concrete. The end product is then a concrete floor from which concrete cilinders pop up, for example 20-30 cm high. The top of those cilinders still remains considerably below what will become the final surface.

On top of those cilinders steel coil springs are added are installed.

On top of those coils, a wooden frame work is added that rests on the steel coil springs. There are two ways of creating the wooden frame work. You either have a two-layer framework or a single-layer framework. In the two-layer framework, the wooden bars that go in one direction are on top of those going into the other direction. This is preferred, but it means that the wooden framework will be thicker than when using single layer. In a single-layer framework, openings are made into the wooden bars that run in one direction, and those that go into the other direction have there ends are inserted into the other wooden bars.

On top of that wooden framework your floor is laid, i.e. wooden planks running in one direction.

So basically, your floor rests on a wooden floor, on steel coils and on concrete pilar leaving below a considerable space that may well be 60 cm deep.

Then, on the floor surroundings, a wooden rim is created that will hold the tatami in place. In between that wooden rim an tatami, a strip of tatami-colored foam is added that can be compressed allowing the tatami being perfectly in place and preventing that the tatami is chafed off from moving against the rim when the floor moves.

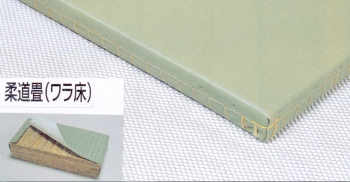

The tatami themselves are a challenge too. At present, to the best of my knowledge there is no shop in the West where you can acquire actual Japanese jûdô tatami. Buying them from Japan is an expensive job due to customs charges and transportation.

Proper tatami are constructed of layers of different substances of different density. Using special equipment they are then sewn and glued. There also exist special tatami built for putting them directly on a concrete floor. The effect is obviously not the same as with a proper floor. Those tatami are like 7 inches thick and very heavy and I know of no dôjô that has them. Inside those tatami also a wooden layer resting on engineered layers, with other layers on top.

The tatami sold in the West as jûdô tatami are cheap fake copies that have a single layer of polyurethane in them. They are put into a piece of canvas that then is simply glued together, not sewn as they don't have the equipment or technology in the West.

There used to be a company in Germany that had an alternative floor in its catalogue, but I am speaking of the beginning of the 1980s. Since very few dôjô are purpose built in the West, one needs a system that is built on an existing floor. That means your floor will be up rather than equal to the normal floor height. Our old dôjô was like that and was built on instructions received from Abe Ichirô.

There are no companies anymore that produce them in the West. Even for gymnastics they are very hard to find. As far as I know the only ones that sometimes still do are for cheerleading floors. The gymnastics floors, like the commercially available jûdô floors in the West have switched to foam blocks. It's much cheaper and much simpler, but the effect is by far not comparable. The standards explained by the FFJDA as the best alternative to steel coil spring floors, use a combination of foam blocks and rubber blocks. There standards provide detailed indications in terms of measurements. There are several companies in France, Germany, and the UK who have them and they are similar to the gymnastic floors, but they remain cheap alternatives. They also do not use individual planks, but use wooden plates with foam glued to it that are then locked together. It's something that every idiot can do himself with the help of a couple of mates.

The proper wooden floors I described above though are also perfect floors (with the tatami removed) for karate, kendô and iaidô, whereas the cheap foam block wooden plates floors aren't really. They aren't properly finished to be used as naked floors, although technically you could put nice wooden planks on it too.

The big problem with the foam block and FFJDA alternatives is that it is still unknown how well they will stand time. The rubber is likely to decay and not respond well to changes in heat, cold and humidity. It may smell. The foam my host bacteria and other stuff. The steel coils really could only rust if it gets really humid, but even that little affects their functionality.

The newest standard instead of steel coil springs uses hydraulic 'springs'. Well, they aren't really 'springs'. They provide excellent resilience, but the major problem is what if one breaks down and leaks ? You would need to break up your floor to remove it, and frankly you would likely not even know whether one and if so, which one is a leading unless somewhere in your floor you have a window, or the space is so large that you can get into it to verify it yourself. Another problem is that hydraulic fluid, at least some hydraulic fluid is suspected of being carcinogenic. So, it needs to be carefully handled with gloves, and I don't know the long-term health effects of hydraulics used in closed-off spaces. I would imagine that since this is contemporary standard material that really there isn't any contact between they hydraulics and the outside world, but ... all things can fail ...